Sunner India Machines | Hitachi Power Tools | D&H | APS Welding Machines | SAP Industries | Advani | Weld Craft | JK Files | Alfa Welding Products | Messer Cutting Systems | Karam Safety Products | Strong Wires | Jhalani Hand Tools | Ador Welding | Shital Welding Wires | Mangalam Welding Electrodes | Bekaert | Dewalt Power Tools | Weldfast Electrodes | Everest Tools | Premier Welding Wires | Honavar Electrodes | Rilon Welding Machines | Anand Arc | Norton Abrasives | Bosch | Weldwell | Kuang Tai | Esab | Flexi Cut | Swastik Weld | Misatu | Addison | Dyeglo | Hyundai | Callington | KPT | Welspring | Abracut | Taparia | Miranada Tools | Cumi | Venus | IT

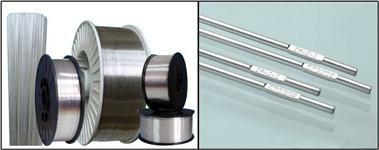

Products / TIG Welding Filler Wires >>

STAINLESS STELL TIG WELDING WIRE

TIG Welding

In TIG welding, the arc is struck between the workpiece and the non-consumable electrode like thoriated tungsten for welding of ferrous materials and zirconated tungsten for aluminum. The consumable wire is melted in the arc atmosphere and the inert gases like argon or helium or their mixture are used as shielding gases. TIG is extremely suitable for joining thin sheets and tubes, and for making root pass welding in pipes, since the heat input in this process is minimal. TIG welds do not cause any undercuts or excessive penetration and give smooth welds. TIG welds provide superior quality weld metal, but the productivity is low.

MIG Welding

Gas-Metal-Arc welding is generally called MIG (Metal Inert Gas) welding, int this process, the consumabloe travels through a nozzle and a top before it strikes an arc with the workpiece. The arc atmosphere is shielded by gases like:

I) 100% Argon.

II) 99% Argon with 1% Oxygen.

III) 97% Argon with 3& Carbon Dioxide

MIG welding is a high-productivity process. MIG welding doesnt need expensive machinery and the welding machines are easily transportable, making this process very popular on construction sites. In MIG welding shielding gas, welding parameters, and the consumable assume an important role. Shielding gases are chosen taking quality, cost and operatibility into consideration.

Normal Grade

304L,308L,308H, 308LSi, 309LMo, 310, 312, 316, 316H, 316L, 316LSi, 317, 317Si, 318Si, 321, 347, 347Si, 410, 420, 430, 409, 409Cb, 409Ti, 410NiMo, 430LNb, 2209, 904L

Range:

Packaging Details

|

Description |

Packing |

Length (mm) |

Size (mm) |

Weight |

|

TIG Rods |

Corrogated Box |

1000 |

4.0, 3.15, 2.5, 2.0, 1.6 |

5 Kgs |

|

MIG Wire |

Plastic Spools |

- |

1.6, 1.2, 0.8 |

12.5 Kgs. |

|

SAW Wire |

Metal |

- |

4.0, 3.15, 2.5 |

25Kgs |

MILD STEEL TIG WELDING WIRES

Carbon Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 1.04 percent.

The term “carbon steel” may also be used in reference to steel, which is not stainless steel; in this use carbon steel may include alloy steels.

As the carbon content rises, steel has the ability to become harder and stronger through heat-treating, but this also makes it less ductile. Regardless of the heat treatment, higher carbon content reduces weld ability. In carbon steels, the higher carbon content lowers the melting point.

We, provide our customer with best quality wires to attain utmost satisfaction.

|

Grade |

Size |

Application |

|

ER – 70S 2 |

TIG: 1.6, 2.0, 2.4, 3.2, 4.0 MIG:0.6, 0.8, 1.2, 1.6 |

For welding of mild and 490 N/mm2 steel. Espeically suited for root pass of pipes, offshore rigs and structural |

|

ER – 80S B2 |

TIG: 1.6, 2.0, 2.4, 3.2, 4.0 MIG:0.6, 0.8, 1.2, 1.6 |

It is designed for welding on 1-1/4 Cr ½ Mo steels |

|

ER-80S-B8 |

TIG: 1.6, 2.0, 2.4, 3.2, 4.0 MIG:0.6, 0.8, 1.2, 1.6 |

For welding of 9% Cr-1% Mo steel |

|

ER-80S-B6 |

TIG: 1.6, 2.0, 2.4, 3.2, 4.0 MIG:0.6, 0.8, 1.2, 1.6 |

It is designed for welding of material of similar composition for high temperature service conditions. |

|

ER-80S D2 |

TIG: 1.6, 2.0, 2.4, 3.2, 4.0 MIG:0.6, 0.8, 1.2, 1.6 |

It is low alloy steel wire with 2% Manganese and 0.5% molybdenum as alloying elements. |

|

ER-80S-Ni1 |

TIG: 1.6, 2.0, 2.4, 3.2, 4.0 MIG:0.6, 0.8, 1.2, 1.6 |

It is used for welding low alloy high strength steels requiring good toughness at temperature as low as -40 degree F. |

|

ER-90S-B3 |

TIG: 1.6, 2.0, 2.4, 3.2, 4.0 MIG:0.6, 0.8, 1.2, 1.6 |

It is designed for welding 2-1/4 Cr 1 Mo steels |

|

ER-90S-B9 |

TIG: 1.6, 2.0, 2.4, 3.2, 4.0 MIG:0.6, 0.8, 1.2, 1.6 |

It is designed to weld high temperature steels for hot hydrogen services and is suitable for 9% Chromium steels such as P91 and F91. |

Packaging: In Tig Form: 5 kgs ; In Mig Form: 12.5kg

ALUMINIUM TIG WELDING WIRES

Aluminium alloys with a wide range of properties are used in engineering structures. Selecting the right alloy for a given application entails considerations of its tensile strength, density, ductility, malleability, workability, weldability, and corrosion resistance, to name a few.

Uses of Aluminium Alloys

Aluminium when combined with other metals gives strength and specific characteristics for a particular use. Aluminium alloys are extensively used in the production of automotive engine parts. The huge array of quality Aluminium is used in various applications like transport, packaging, electrical application, medicine, and construction of homes and furniture. The high altitude flying is not possible without the huge pressures and stresses involved in the strong aluminum alloys.

Products in Aluminium Alloy

I) 5% Silicon ER 4043 / NG21

II) 12% Silicon ER4047 / NG2

III) 5% Magnesium - ER 5356 / NG6

IV) Pure Aluminium ER 1100 / AL 1B

Packaging Details

|

Description |

Packaging |

Length (mm) |

Size (mm) |

Weight |

|

TIG Rods |

Corrugated Box |

1000 |

3.2, 2.4, 2.0, 1.6 |

5 Kgs |

|

MIG Wire |

Plastic Spools |

- |

1.6, 1.2, 0.8 |

Aluminium – 6 Kgs |

We supply only ISO certified Aluminum Alloy.

We cater to your welding requirements of Aluminum Alloys in the form of Alfa Welding Aluminum Alloys and FSH Aluminum Alloys.

SILVER BRAZING

Silver Brazing Alloys are easy to use, possess high strength impact with short melting ranges, free flowing and versatile. They have outstanding flow characteristics and mechanical properties. These are available in forms of wire, foils or shims, preformed wires or strips, granules, rings and paste or powder. Besides, these can be customised as per clients specifications and applications.

Uses Automotive industry uses brazing extensively, especially for brazing aluminum radiators, which use tube-to-fin and tube-to-header joints.

Brazing is also used in pipe and tube applications to extend length, fabricate shapes, join dissimilar materials, and to ensure a water or pressure tight joint. Common base metals include aluminum and its alloy, copper and alloy, steel and stainless steel.

Brazing applications extend to microwave reflectors, satellites, cameras, and other sophisticated instrumentation. Common base metals used include oxygen free copper, nickel, stainless steel, copper- nickel alloy, iron-nickel-cobalt alloys, and tungsten.

Products in Silver Brazing Alloys

Silver Brazing Rods & Foils

Ranges: 50%, 43%, 35%, 30%, 14%, 5%, 2%

Packaging Details

|

Description |

Packing |

Length (mm) |

Size (mm) |

Weight |

|

TIG Rods |

Corrogated Box |

500 |

1.6 |

1 Kgs |

|

SHIM/ Foil |

- |

- |

- |

On Request |

We cater to your welding requirements of Silver Brazing Alloys in the form of Agrawal Co. ( AS PER IS 2927) Silver Brazing Alloys.

Copyright protected by SUDHANSHU ASSOCIATES | Powered by

PROLIFIC WORLD